New method for degradation of waste polystyrene

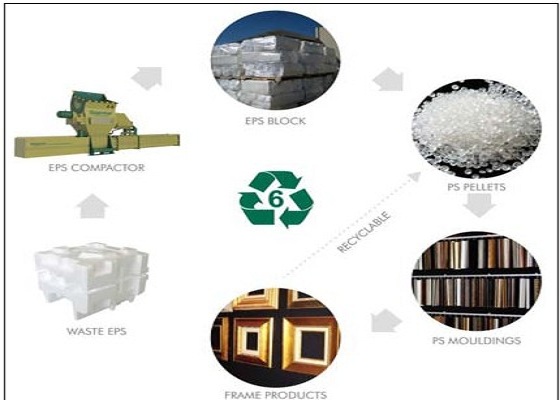

As the polystyrene is always qualitative light, heat insulation, sound-absorbing, shock absorption, etc, It is widely used in building, furniture and other industries, but how to recycle it is a big problem.

If we use landfill or incineration, that will make a lot of pollution.

According to incomplete statistics, at present, in the Nordic countries and Japan PS foamed plastics recycling utilization rate is 72%, South Korea PS foamed plastics recycling utilization rate is 64%, while other countries and regions, PS foam plastics recycling utilization rate was only about 10-30%. In our country, due to the recovery mechanism is not perfect enough, lead to 70% buried or burned, only about 30% recycled, most waste polystyrene material has not been effective recovery and utilization, caused serious environmental pollution. Severe resource crisis and environmental pollution, forcing we must increase the resource recycling and reusing, recycling and utilization of green development road.

Usually, using EPS briquetting can effectively reduce waste foam plastic compression processing, now developed a comprehensive utilization of waste polystyrene technology, can effectively overcome the traditional foam plastics processing method of faults. With orange oil dissolved waste polystyrene foam plastic, again by adding precipitating agent (such as alcohols, ethers, organic reagents) polystyrene precipitation, filtration for polystyrene can be recycled, and finally by adding auxiliary solvent and precipitant separated, and recovered solvents, additives and precipitating agent can be separated by distillation.

This process is simple, polystyrene and solvent recovery efficiency is high, the polystyrene performance and standard performance difference is not big, can be directly used in the preparation of a new polystyrene foam; The reagents used safe non-toxic, does not produce secondary pollution, and can be recycled, solvent recovery more than 95%. The whole craft simply heating, saves energy, and reduce the production cost. The technology has been applied for two national invention patents, utility models.

Foam plastics recycling value is high, if you can solve the problem of recycling waste styrene foam. I believe that waste plastic foam value can bring us more profit.