Hospital Uses Densifier to Recycle Polystyrene Foam

The cafeteria and food services department at the University of Maryland's Baltimore Washington Medical Center uses a large amount of polystyrene foam to implement a polystyrene foam recycling program to protect the environment.

Compared to ordinary plastic and paper products, polystyrene foam is cheaper and it has good insulating factors. It also provides heat retention when people are sending things out of the department. One Anne Arundel County hospital uses a great deal of polystyrene foam as its superiority. However, every coin has two sides. It is waterproof and can’t be decomposed easily by the soil and water. To reduce the department’s waste and protect environmet, the hospital is making every effort to "go green".

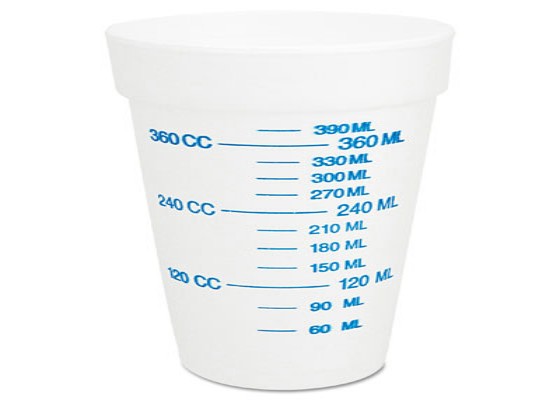

Workers in the hospital can recycle polystyrene foam like they do with recycled paper, plastic and aluminum, thanks to a densifier machine. The denisifier can compress all the air of the foam products. The department has already separated other trash like bottles and paper from packaging foam, foam cups and foam containers. It also added an extra bin for polystyrene foam.

Therefore, workers can just throw foam scraps into the belly of the machine. And then large foam will be compressed into long cylinders. The cylinders are clean, white, hard and dried. Then they will be taken back to recycling facility and be sold out to make pellets. The pellets also can bring profits. They are not the final products. Those pellets are then used to make anything with polystyrene, such as CD cases, moldings and picture frames.

There is hoping that the foam-related industries can think deeply before acting. It’s our duty to recycle polystyrene to take care of the environment.