GREENMAX helps Tecno Profili complete foam recycling and economic double closed loop in Italy

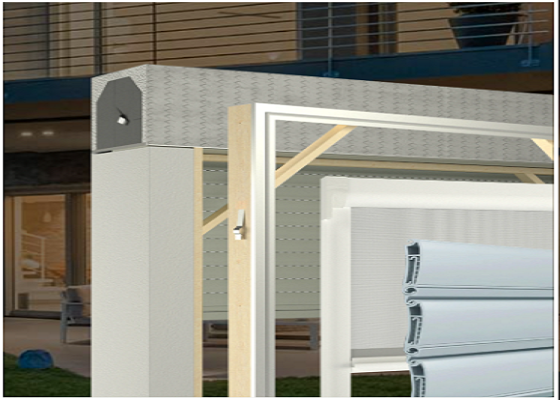

Tecno Profili is a building materials supplier in central Italy and one of the important partners of INTCO Recycling. During the cutting process, some EPS and XPS foam scraps will be produced. Through our customer's introduction, he learned about the recycling methods of foam waste and its recycling economics. At the same time, he also got in touch with GREENMAX offered by INTCO Recycling.

Before understanding the foam recycling method, customers' waste materials were collected by recyclers for free, but starting from 2024, they will need to pay for processing. The waste generated during the production process not only takes up a lot of space in the factory, but also poses certain safety risks; at the same time, considering that recyclers cannot provide door-to-door recycling services in a timely manner and need to pay afterwards, these reasons have prompted customers to consider launching independent foam recycling projects.

The customer's foam waste consists of ordinary EPS and XPS foam, which has a high density but a small amount of waste. Based on this, we recommended GREENMAX foam compactor A-C100 to the customer, which has double crushing and automatic cutting. The double crushing is helpful for crushing high-density foam waste, and the automatic cutting can save labor. The customer is very satisfied with our solution.

In mid-September 2023, we visited the customer on-site. Through on-site communication, after explaining the waste plastic closed-loop model of GREENMAX, the customer trusted us more and decided to place an order for a foam compactor on site. In order to ensure that customers can receive the machine in 2023, it will not affect customer subsidy applications and speed up the production progress. In the end, the customer received the foam recycling machine as scheduled and used it normally. We also helped the customer successfully apply for Italian financial subsidies.

After the foam compactor arrives at the customer's factory, GREENMAX provides customers with on-site installation and usage guidance services. Our timely service and simple and smart touch operations allow customers to quickly master the usage and use the machine easily. Currently, the customer uses this foam recycling machine normally, and its pressed foam waste will be purchased and recycled by its XPS supplier. The customer can also choose to sell the compressed material to Inko Recycling, because we have a mature and complete recycling closed loop. EPS compressed foam materials are a seller's market in Europe, and our closed-loop recycling model allows customers to have no worries!

The volume of waste foam compressed by GREENMAX foam compactor is reduced to one-fifth of its original size, which not only greatly saves space, but also creates profits.