GREENMAX EPS Densifier helps Malaysia F.E.FOAM recycle EPS dust and improve economic efficiency

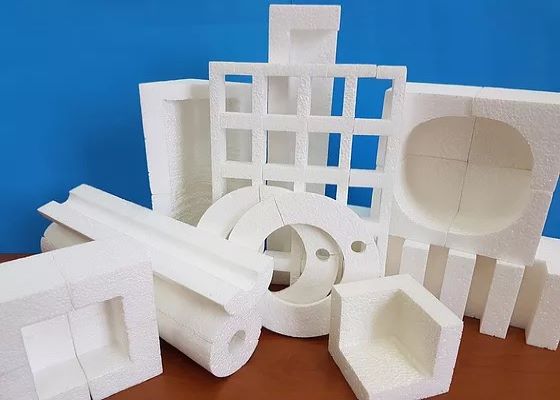

F.E.FOAM is located in Malaysia and has a history of nearly 30 years in the EPS manufacturing industry, providing EPS products for construction, industrial applications, packaging, wall insulation, etc. F.E.FOAM also provides personalized customization services to meet the special needs of various products due to their shape, size, and nature.

In the EPS customized production process of F.E.FOAM, EPS powder and leftovers will be produced. As a producer of EPS, F.E.FOAM has a high sense of social responsibility. In order to help itself and downstream buyers develop a circular economy and prevent white EPS pollution, it actively requires the recycling of EPS leftovers to comply with the development trend of EPS recycling and environmental protection.

F.E.FOAM's previous EPS handling way was to directly throw away the EPS dust and leftovers produced and recovered. Because the density is different, it is not easy to reuse it in the product, which not only causes a waste of resources but also is not the most environmentally friendly treatment method.

F.E.FOAM has a unique geographical location and a good business development model. It is close to surrounding cities and has a well-developed transportation network. With the healthy development of business, more and more wastes need to be processed, and the disadvantages of not achieving a circular economy have gradually become prominent. For this reason, F.E.FOAM, after learning about GREENMAX's professionalism and strength, approached us in March 2021 to consult on the EPS dust recycling program.

According to F.E.FOAM's actual situation and material characteristics, GREENMAX recommended several models that suit them. Taking into account the cost and space issues, F.E.FOAM finally chose the M-C100 EPS densifier, which not only found a way to solve waste for itself and its customers, strengthened cooperation with customers, but also demonstrated its sense of social responsibility and established a good corporate image.

In April of the same year, F.E.FOAM quickly chose the GRRENMAX M-C100 EPS densifier customized by Greenmax for their needs, and it was put into use in Sep. of the year, which smoothly solved the shortcomings of the company’s production and increased economic benefits through the sale of recycled EPS. These processed EPS will also be recycled by INTCO Recycling and used in the production of frame products in order to achieve a circular economy.