How to recycle EPP packaging in California?

EPP has been widely used in the automobile and packaging industry, especially in the packaging of export products. As long as the industry comes into using EPP, dealing with it is a problem. A small amount of EPP waste can be easily disposed of and can be made into handicrafts or sent to a nearby recycling station. But for enterprises, the disposal of a large number of EPP waste is a problem. In California, relevant manufacturers have adopted EPP recycling measures to deal with this material.

Generally speaking, there are two ways to do EPP recycling:

1 incinerator combustion

EPP material is a safe and environmental protection material. If it is put into the incinerator for combustion, it can produce power resources without discharging toxic gas.

2. Machine recycling

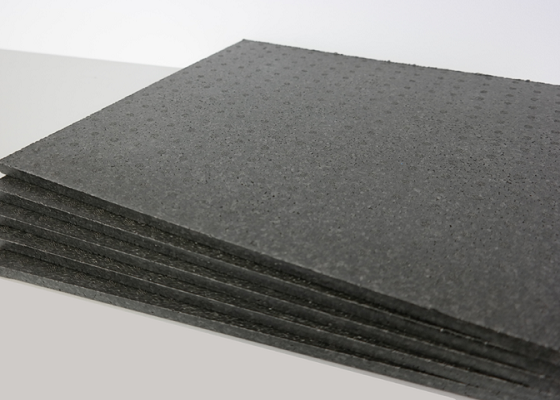

When EPP is thrown into a special EPP recycling machine, it will be cut into pieces and then be heated and compressed into more compact EPP blocks, which can be sold to pellets manufacturers at a high price.

Between the two, most California manufacturers choose the second one due to the price of densified EPP material is relatively high. If the waste EPP is sent for incineration, it is obviously not cost-effective. It is the intention of these manufacturers to make full use of valuable resources. By EPP machine recycling, manufacturers can sell densified EPP ingots at a high price, making more money than burning. Moreover, if you judge that the market demand for future EPP ingots will increase, you can store the EPP ingots there. When the price is high enough to sell, INTCO will provide you with price remind services, because INTCO has a business of purchasing these EPP ingots.

INTCO has a complete industrial chain of EPP recycling, which provides GREENMAX EPP recycling machines for manufacturers, purchasing recycled ingots, making pellets, and produce photo frames. It not only contributes to environmental protection but also helps manufacturers solve problems.