Styrofoam compactor makes plastic recycling easier and more international

The recycling of Styrofoam should not be limited to the United States. As a global recycling and manufacturing company, INTCO Recycling recycling scope for Styrofoam recycling is global. In recent years, European countries have also paid special attention to the recycling of styrofoam. According to estimates from the Ministry of Ecological Transition, nearly 2.2 million tonnes of household, industrial and commercial plastic packaging are placed on the market in France each year.

Styrofoam alone represents more than 350,000 tonnes per year, or 7% of plastic materials used in all sectors combined. To this day, these household polystyrene packaging remains very poorly recycled (around 3 to 4%), outside of France. They also generate significant pollution: Styrofoam fragments are in fact one of the ten most common waste items found on beaches and in the seabed, alongside cigarette butts or plastic bottles.

.jpg)

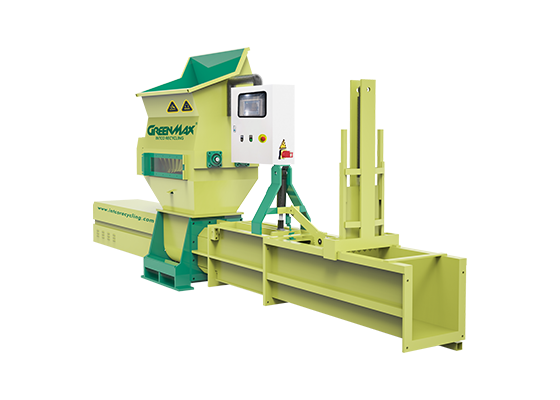

Compagnons d'Emmaüs Montbéliard invested 40,000 euros to purchase a piece of equipment to help recycle styrofoam, mainly to discharge the air from the air-filled styrofoam. The compression ratio of the styrofoam compactor designed and manufactured by GREENMAX, a subsidiary of INTCO Recycling, can reach 50:1. The operation of this styrofoam compactor mainly relies on the support of cold pressing technology. At present, cold pressing technology is not a recycling technology with the highest compression ratio, but it is a recycling technology with less energy consumption. This recycling technology is also very popular among customers in Europe.

The waste processed by Styrofoam compactor usually turns into dense styrofoam blocs, which saves transportation costs to a certain extent. Because if you want to completely reuse styrofoam, these styrofoam waste needs to be transported to professional manufacturing plants for reprocessing. , so in this process we have to balance the investment in transportation. Using equipment to squeeze out the air in waste is an efficient solution.

At present, more and more customers are pursuing a high degree of automation of equipment, so engineers equipped the styrofoam compactor with automatic cutting equipment. The cutting length is controlled through the touch screen (PLC central control system) on the machine, realizing the requirement of automatic cutting and helping Saves labor investment.

.png)