The recycling activities at Norman Church may broaden the types of recycled foam with foam compactor

The University Lutheran Church in Norman has been insisting on recycling polystyrene foam in recent years. They mainly recycle polystyrene foam. Recently, the organization recycled a total of 9,000 pounds of recycled materials. It all started in 2021 when Cathy Bowden applied for a grant to purchase a piece of equipment for compressing polystyrene foam, a polystyrene densifier. Bowden and volunteers run the polystyrene densifier about every 10 days, or when the room where all the styrofoam is stored is filled to capacity. Recycling in the area is ongoing and orderly, thanks to the polystyrene densifier, and the correct application of recycling equipment is key to a successful recycling.

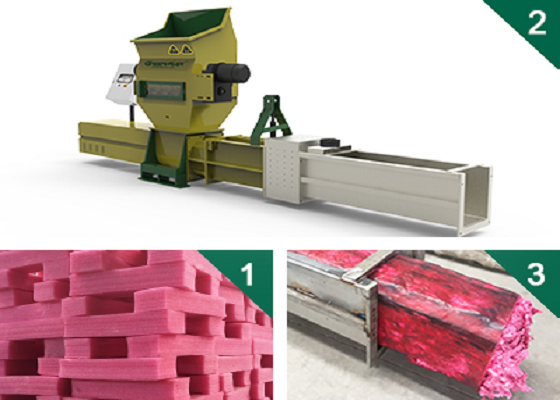

In the recycling process, we will inevitably see other foams other than polystyrene foam donated by some people, especially the soft foam we often say. This kind of foam is usually Polyethylene foam. This kind of foam is actually used as packaging. The shock absorption ability of polystyrene foam is similar to that of polystyrene foam, but it is softer and can be bent into the shape we want at will. Usually, this material is used to package fragile products, such as the corners of mirrors, furniture, etc. So can this kind of foam be recycled? In fact, some recycling equipment can recycle polystyrene foam and polyethylene foam at the same time, and soft foam no longer needs to be rejected in recycling activities. GREENMAX foam compactor can recycle both polystyrene foam and polyethylene foam. Foam compactor crushes foam and then extrudes it with a screw. The reason why Polyethylene foam can be recycled is that there is a hot-melt ring at the outlet, which can heat the surface of dense Polyethylene foam blocs to form a closed protective layer, preventing Polyethylene foam fragments from rebounding during compression and causing scattering.

The foam compactor Zeus series manufactured by Intco Recycling's GREENMAX Machine can achieve a compression ratio of 50:1 during the recycling process, which effectively saves money for the recycling work.